Silence in the industrial sector usually signals one of two things: stagnation, or intense execution. For SENSAiO, 2025 was a year of the latter.

While the broader IoT market discussed future trends and concepts, our engineering and operations teams were deployed in the field, turning pilot projects into permanent infrastructure.

The results validate our core philosophy: Heavy industry demands heavy infrastructure.

In 2025, SENSAiO achieved a 2x increase in turnover and reached EBITDA positivity. For our clients—major operators in Oil & Gas and Mining—this financial stability is as critical as our technical specifications. It proves that “Robust IoT” is not just a technology; it is a sustainable, scalable business model that will be here to support your assets for the next decade.

The 2026–2031 market outlook predicted a shift toward “Brownfield Retrofits”—adding smart monitoring to existing, aging assets without laying new cables. Our 2025 deployment data confirms this shift is already underway.

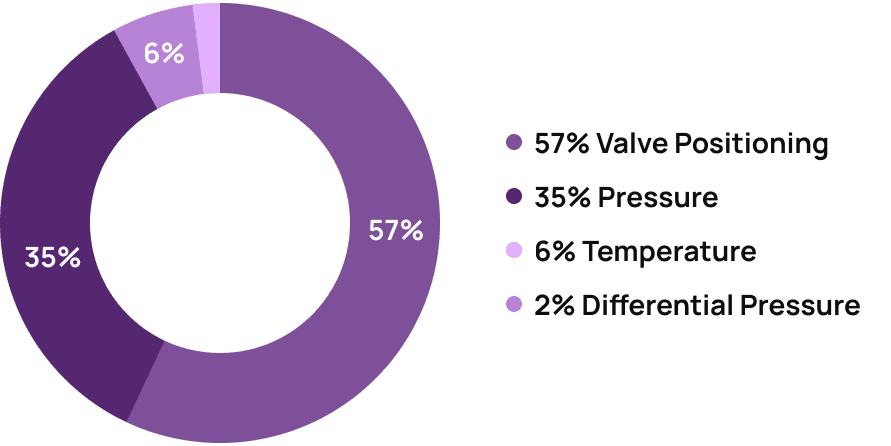

The Analysis:

SENSAiO is engineered for resilience. Our geographic spread validates our Material Integrity strategy.In 2025, our footprint expanded to 34 countries across 5 key industries (Oil & Gas Upstream/Downstream, Mining, Pharmaceutical, and Offshore).

While consumer-grade IoT often relies on engineered plastics that degrade under UV and thermal stress, SENSAiO utilizes die-cast aluminum and stainless steel housings. This robust construction ensures consistent performance in the extreme heat of Middle Eastern deserts and the corrosive salt spray of the North Sea.

We build for the “Operational Realist”—the engineer who values Zero-Maintenance Infrastructure.

Our “install and forget” philosophy reduces human intervention in hazardous zones, directly lowering safety risks. Features like in-situ battery replacement (changing the battery while the sensor remains mounted) ensure that maintaining the network never becomes a burden on operations.

The ability to integrate SENSAiO data into our existing SCADA without being forced into a proprietary cloud was the deciding factor. We own the network; SENSAiO provides the reliability.

– Lead System Integrator, Southeast Asia

Scaling from hundreds to thousands of units requires more than good engineering; it requires a robust supply chain. In 2025, we restructured our operations to support mass production.

To understand where we are going, it is important to look at the timeline.

Since our founding in 2019, SENSAiO spent five years (2019–2024) validating our technology, deploying 1,000 sensors in rigorous proof-of-concept and pilot programs. 2025 marked the inflection point: Market Maturity.

In just one year, we more than doubled our total historical deployments to reach 2,600 active units. This ramp-up confirms that the industrial market has moved from “Testing” to “Mass Production.”

Coming Q1 2026: We are expanding to Malaysia with a new R&D and Training Centre.

To our clients and partners: Thank you for trusting the standard. We are ready to scale with you.

Ready to deploy? [Contact our Engineering Team] | [Download the 2026 Product Catalogs]