Land-disposed Waste or simply Landfill is a carefully designed and engineered structure that is used for the disposal of solid waste materials on land. It is designed to be environmentally responsible solutions for solid waste disposal, but one of the major risks is Landfill Gas Fire and Explosion, and it poses a grave environmental and safety threat that spans the globe, affecting nations across the world.

From the United States and Canada to India, Indonesia, Australia, and the United Kingdom, this issue knows no borders. It is estimated that open burning of waste produces 11% of global black carbon emissions*.

These fires, occurring when waste materials within landfill sites ignite and burn, often due to spontaneous combustion, methane gas buildup, or unauthorized burning, have severe consequences for the environment, public health, and infrastructure.

However, they pose several complications and challenges:

1. Air pollution

Burning waste releases various pollutants, such as particulate matter, carbon monoxide, nitrogen oxides, and volatile organic compounds, into the air. These pollutants can have adverse effects on human health, particularly respiratory problems, and contribute to poor air quality.

2. Soil and groundwater contamination

The ash and residues from landfill fires can contain toxic substances, which can leach into the soil and potentially contaminate groundwater sources if not properly contained.

3. Greenhouse gas emissions

Landfill fires contribute to the release of greenhouse gases, such as carbon dioxide and methane, which exacerbate climate change.

4. Hazardous material exposure

If hazardous materials, such as chemical waste or electronic components, are present in the landfill, their combustion can release toxic substances into the environment, posing significant health risks.

5. Infrastructure damage

Intense heat from landfill fires can damage nearby structures, roads, and utilities, leading to costly repairs and disruptions

According to a report from SUEZ Energy in France**, the most frequently occurring accident in landfill is fire (59% of recorded incidents), the main causes of which are:

1- Malicious acts

2- Existence of electrical problems

3- Presence of unwanted waste

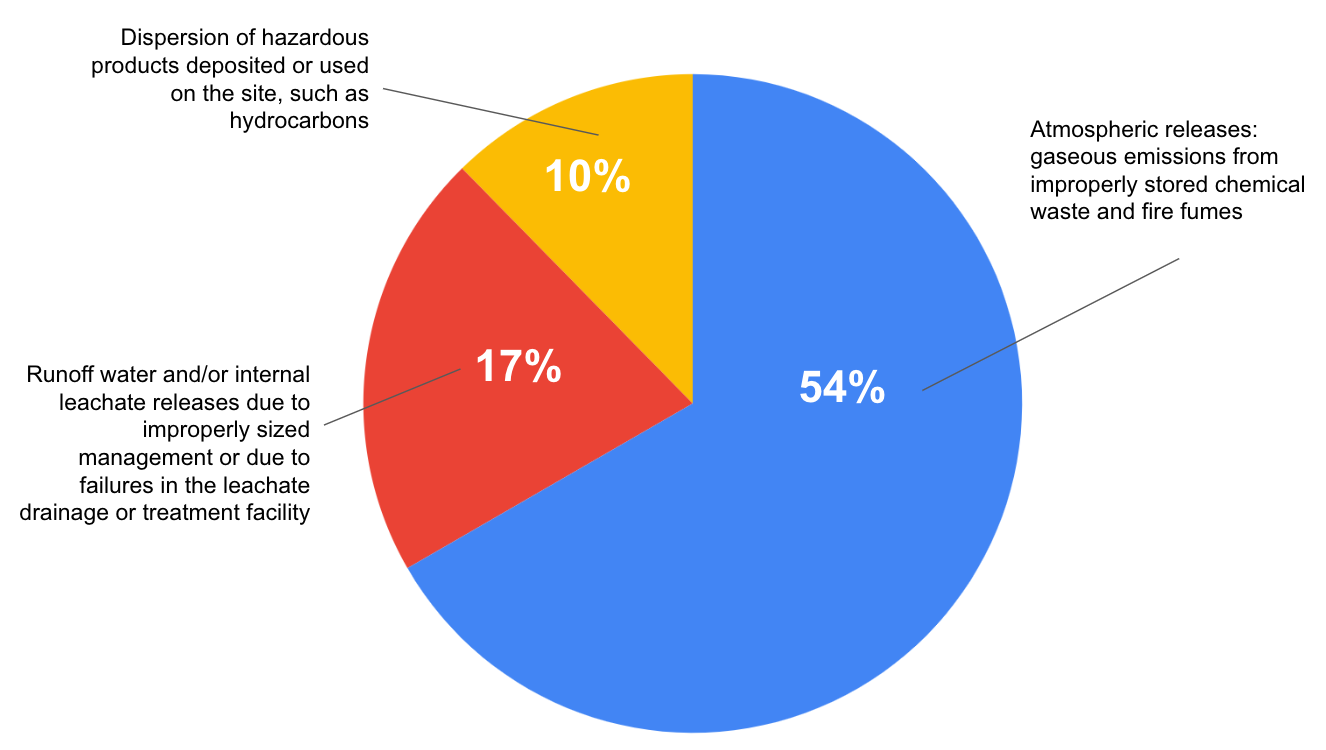

In general, the dangerous releases, which account for more than 34% of the accidents or incidents occurring in non-hazardous waste landfills, consist of:

Incidents of an explosion originate from either:

– Storage of prohibited waste (chemical products, ammunition/explosives, etc.)

– Biogas leaks

Here is a summary of the most common methods used to prevent landfill fires.

| Solutions | Pros | Cons |

|---|---|---|

| Gas collection and venting systems | Collect and vent methane gas generated by decomposing waste, reducing the risk of gas buildup and subsequent fires | Installation and maintenance can be costly. Systems may not be 100% effective in preventing fires |

| Landfill cover and compaction | Proper covering and compaction of waste layers can reduce the oxygen supply and inhibit combustion | Improper implementation or damage to the cover can negate its effectiveness. Compaction alone may not prevent spontaneous combustion |

| Fire detection and suppression systems | Early detection and suppression can help control and extinguish landfill fires before they escalate | Can be expensive to install and maintain. May not be effective for deep-seated or widespread fires |

| Waste segregation and monitoring | Separating incompatible waste materials and monitoring for heat buildup can reduce the risk of spontaneous combustion | Effective waste segregation and monitoring require significant resources and vigilance May not be feasible for all landfill operations |

A comprehensive approach combining multiple strategies is necessary to effectively prevent and manage landfill fires:

– Stringent waste acceptance and segregation protocols

– Advanced gas collection and monitoring systems

– Effective landfill cover and compaction techniques

– Rapid detection and response measures

– Incorporation of sustainable waste management practices

– Robust regulatory framework and enforcement

– Ongoing research and technology development

The state of Victoria in Australia has issued a detail guide to monitor landfill gas emissions**, with the most important being:

– Use appropriate instruments that meet the specified minimum performance criteria for monitoring methane, carbon dioxide, oxygen, relative pressure, and gas flow rate.

– Monitor methane surface emissions from final caps and intermediate covers using a walkover survey method following the detailed procedures. This is for assessing compliance with gas action levels in the Best Practice Environmental Management (BPEM) guidelines.

– Monitor subsurface geology landfill gas concentrations, relative pressure and gas flow rate using extractive landfill gas analyzers in dedicated gas monitoring bores. This data is used to assess compliance with BPEM action levels and conduct landfill gas risk assessments.

– Monitor methane concentrations in subsurface services and buildings/structures on or adjacent to the landfill using low-concentration methane detectors.

– Notify the EPA within 24 hours if monitoring shows the BPEM landfill gas action levels are exceeded, except where surface emission exceedances are rectified within 24 hours.

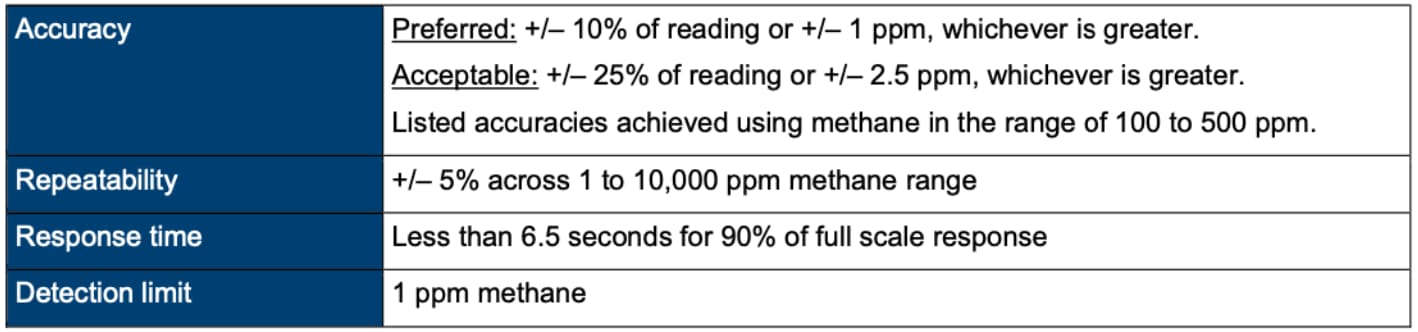

The guideline outline detectors’ minimum performance specification for low-concentration methane as follow:

Similar guidelines are issued by other countries’ environmental Authorities.

By regulation, Australian Landfill operators must collect gas emission to avoid its release into the atmosphere and prevent fire or explosion.

Previously the monitoring of gas was done with cabled sensors which suffer from multiple problems such as rats eating the cables, plastic PVC pipes where cables pass-thought collapsing, water flooding, installation and maintenance cost.

Moreover, the gas buildup in landfill requires sensors able to monitor differential pressure with extremely low pressure (millibars) from -30mbar to 150mbar.

SENSAiO provided a cost effective solution solving all challenges

1- Pressure (min): 40kPa (or 0.4bar)

2- Communication: Wireless (Lorawan)

3- Battery life: up to 10 years (ultra low power)

4- Robust body in Stainless Steel

5- Certification: IECEx

6- Maintenance: None

7 SENSAiO Pressure sensors are in service since May 2022.

While SENSAiO cannot directly enforce government regulations, our innovative sensor technology can empower landfill operators in any country with the tools necessary to enhance their monitoring capabilities, improve safety, and contribute to landfill fire prevention and management.

Technical Details about SENSAiO ATEX Pressure Sensor: click here

Resources:

*https://climatechampions.unfccc.int/a-clarion-call-to-reduce-and-phase-out-of-open-waste-burning/

**https://www.bouches-du-rhone.gouv.fr/Publications/Publications-environnementales/Etude-d-impact-avis-de-l-autorite-environnementale-AE/Les-Pennes-Mirabeau

***https://www.epa.vic.gov.au/about-epa/publications/1684