In the arena of industrial IoT Valve Position Sensor, Aloxy and SENSAiO stand as prominent contenders, offering cutting-edge solutions.

This comprehensive analysis pits their flagship products against each other, dissecting their advanced features, performance capabilities, and industry applications.

From technological architectures to data analytics, remote access to proven use cases across sectors like oil/gas, chemical, and water treatment, we’ll scrutinize every aspect to help you determine which valve positioning system suits your industry best.

Aloxy’s valve monitoring sensor uses IMU (Inertial Measurement Unit) with Vector Magnetometer (US Patent) to capture valve movement data during operation of the hand wheel or lever.

It is wireless and can be mounted directly into the valve, providing raw data that can be communicated over a low power network like LoRaWAN or DASH7. Aloxy’s sensor is certified ATEX IECEx Zone 1 (class 1 div 2) for gas.

Data are collected and can be sent to Aloxy’s proprietary application server or third party network server .

The sensor can be calibrated and provides feedback on open, closed, and intermediate valve positions. It is easy and fast to install Aloxy’s sensor with bolts or straps., it does not require customized brackets.

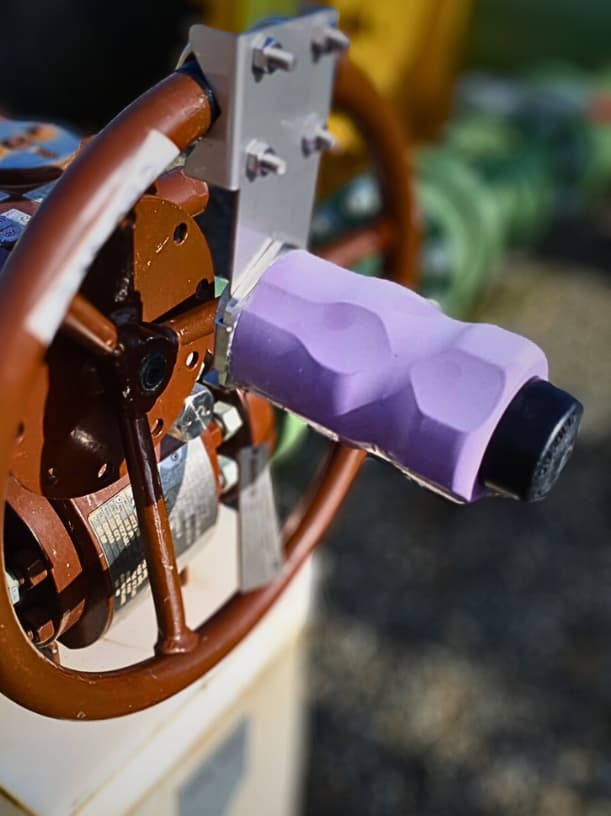

SENSAiO’s valve positioning sensor is also wireless and uses LoRaWAN for remote communication. It is designed for harsh environments and can be installed on the hand wheel or lever of the valve.

The sensor uses IMU (Inertial Measurement Unit) with Absolute Magnetometer and has a long-range, ATEX IECEx Zone 0 (class 1 div 1) certified for gas and dust (for mining or chemical powder). It allows continuous monitoring, which enables real-time notification of any shift in valve position automatically.

The sensor can be configured using an Android or iOS smartphone with Bluetooth 5 and has a modular structure for easy maintenance, mounting bracket and intuitive user interface for calibration. It is license-free and agnostic, it can connect to any IOT platform and Network server.

Both solutions aim to improve safety and efficiency in industrial processes by providing real-time valve position information. In terms of reliability, the Aloxy design is made from 100% plastic polymer. Plastic polymer has the advantage of being lightweight, but also it is sensitive to UV and poor hydromorphic tolerances, which can lead to surface cracking over time. In contrast, SENSAiO is designed in aluminum and stainless steel material, they offer a 5-year guarantee and reconditioning after 10 years of service, also most of their materials are recyclable. Repairability index of 8/10 thanks to its patented design and field replaceable battery.

The battery life of the SENSAiO valve positioning sensor is estimated to be up to 10 years in SF7, depending on the LoRa TX periodicity, while exceeding 3 years in SF12. The Aloxy valve position monitoring sensor has a battery life of 5 to 6 years in SF7 while drop to 1 to 3 years in SF12 due to 30% less battery capacity and heavy processing complexity of vectoriel magnetometer.

The maximum range of the Sensa valve positioning sensor is up to 10km Line-Of-Sight (SF12) with RF max power of 14 dBm ERP thanks to unique antenna design by resonance and the Aloxy valve position monitoring sensor uses 10 dBm radio frequency that limits its range to <2km (SF12).

Details on technology choice for their IMU (Inertial Measurement Unit)

While both solutions employ accelerometers and gyroscopes, their approaches diverge when it comes to the inclusion of magnetometers.

Aloxy’s US patented Vector Magnetometer provides a higher accuracy in complex environments with non-uniform magnetic fields, such as indoor environments or areas with significant magnetic interference. However, it requires additional algorithms increasing computational complexity and battery usage. It may require more intricate calibration procedures to account for sensor biases and misalignments.

SENSAiO’s Absolute Magnetometer provides direct measurements of the Earth’s magnetic field, allowing for absolute orientation determination without additional processing. In order to prevent any disturbances from external magnetic fields, which can affect accuracy, SENSAiO has implemented an internal processing validation to prevent any measurement error.

| Features | SENSAiO | ALOXY |

|---|---|---|

| Technology | IMU (Inertial Measurement Unit) with Accelerometer, Gyroscope and Absolute Magnetometer | IMU (Inertial Measurement Unit) with Accelerometer, Gyroscope and Vector Magnetometer (US Patent) |

| Communication | LoRaWAN | LoRaWAN or DASH7 |

| Radio Frequency | 863MHz – 928MHz Maximum 14 dBm | 863MHz – 928MHz Maximum 10 dBm |

| Communication Range | LoRaWAN up to 10km | DASH7 500m LoRaWAN SF7 500m LoRaWAN SF9 1km LoRaWAN SF12 <2km |

| Local Connectivity | Bluetooth 5.0 | NFC |

| Mounting | Mounted to the valve without alterations | Mounted to the valve without alterations |

| Calibration | Configurable using a smartphone | Not provided |

| Position Feedback | Open, closed, and intermediate positions | Open, closed, and intermediate positions |

| Certifications | ATEX, IECEx and Zone 0 Class 1 Div 1 certified for Gas, Dust and Mining | ATEX, IECEx and Zone 1 Class1 Div2 certified for Gas |

| Battery Capacity | 12,400mAh | 8,500mAh |

| Battery Life | 10 years in SF7 3 years in SF12 | 5 to 6 years in SF7 4 to 5 years in SF9 1 to 3 years in SF12 |

| 12.4 Ah | 8.5 Ah | |

| Sensor Material | Stainless Steel (hardened on request) or Aluminum | TPE and Nylon |

| Sensor Size | 130mm x 59mm (diameter) | Length 88.5mm x Width 41.2mm x Height 50.3mm |

| Sensor Weight | 1000-1500g | 150g |

| Update Rate | Realtime or 100 frames/per day (default) | Not provided |

| Security | AES 128 bit encryption by dedicated secure element | AES 128 bit encryption |

| Data Collection | On-device. Agnostic to any cloud or on-premise. | Aloxy’s IIoT Hub or third-party solution. |

| Membership | No monthly fee | Monthly Membership |

| Price | $$ | $ |

| Total Cost of Ownership | $ | $$ |

When it comes to industrial IoT valve positioning solutions, SENSAiO emerges as a standout choice, offering advanced sensor features housed within a durable body backed by a 5-year guarantee.

While both SENSAiO and Aloxy provide battery-powered wireless solutions leveraging LoRaWAN technology, SENSAiO’s product distinguishes itself with its full certification ATEX/IECEx Zone 0 for gas and dust, license-free operation, and real-time data transmission over 10-kilometer range. Furthermore, SENSAiO’s sensor boasts an exceptional battery life of up to 10 years, minimizing maintenance requirements and associated costs.

However, it’s important to consider the financial implications of these solutions. Although SENSAiO’s sensor offers a lower total cost of ownership over a 10-year period, the initial investment may not align with the budget constraints of certain projects. In such cases, Aloxy’s offering or the TWTG Neon Valve Sensor MT with its lightweight plastic mold body, smaller battery size, and ATEX Zone 1/IECEx Class 1 certification may be more suitable alternatives, depending on the specific requirements and priorities of the application.

Datasheet of SENSAiO’s Valve position Sensor available: here.

Resources:

Manual: Aloxy Pulse Instruction Manual [EN]: https://www.aloxy.io/company/manuals-certificates/

LoRaWAN Valve Position Sensor Datasheet: https://sensa.io/lorawan-atex-valve-position-sensor/